Top 10 Split Core Current Sensors for Accurate Electrical Measurement

In the realm of electrical measurement, precision is paramount. The split core current sensor has emerged as a leading solution for accurate monitoring. As industry expert Dr. John Smith states, "Reliable current sensing is essential for efficient electrical systems." This underscores the importance of selecting the right sensor.

Split core current sensors provide a unique advantage. Their design allows easy installation around existing wires, minimizing downtime. These sensors can measure AC currents with impressive accuracy. Many companies rely on these tools for everyday operations. However, some users overlook factors like calibration and environmental influences. These oversights can lead to significant errors.

Choosing the right split core current sensor can be challenging. The market offers a variety of models with different specifications. Users must consider their specific needs. A sensor that works for one application may underperform in another. It’s essential to assess the operational environment and the desired accuracy level. In a field as precise as electrical measurement, making informed choices is crucial.

Overview of Split Core Current Sensors and Their Applications

Split core current sensors are essential tools for precise electrical measurements. They enable non-intrusive measurement of current in various applications. These sensors are particularly useful in scenarios where traditional measurement methods may not be practical. For instance, you can clamp them around existing wires without needing to disconnect or alter the circuit.

Their design allows for easy installation and portability. Many technicians prefer split core sensors for their versatility. They can be used in residential, commercial, and industrial settings. In homes, they help monitor energy consumption for efficiency. In commercial environments, they facilitate proactive maintenance of electrical systems and devices.

However, not all split core sensors are equal. Some may provide inconsistent readings under certain conditions. Calibration is necessary for optimal performance. Users should be aware of their limitations. That said, these sensors offer valuable insights into electrical systems. Properly integrated, they can significantly enhance energy management strategies.

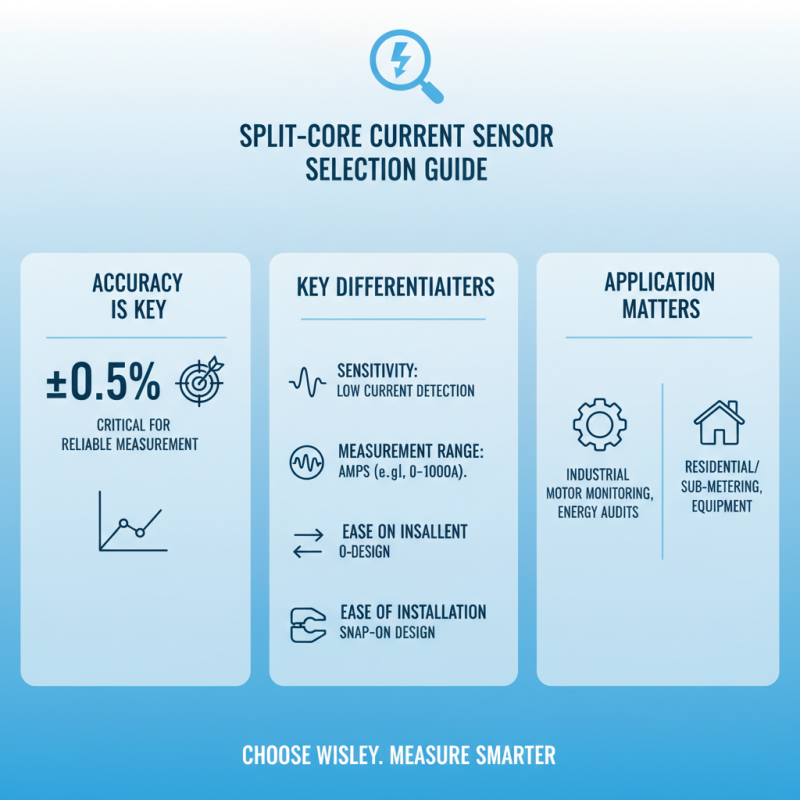

Key Features to Consider When Selecting a Split Core Current Sensor

When selecting a split core current sensor, accuracy is paramount. A 2019 industry report highlighted that sensors with a tolerance of ±1% provide reliable readings for commercial applications. This is crucial for maintaining operational efficiency and safety. In addition, ensure that the sensor can handle a wide range of current. Models capable of measuring from 0 to 600 amps are more versatile and can adapt to various electrical systems.

Installation flexibility is also vital. Split core sensors are favored because they can be clamped onto live wires without disconnecting them. This feature saves time and reduces risks during setup. However, not all sensors have this ease of installation. Consider those with a smaller profile for tight spaces. Furthermore, the durability of the sensor matters. A study indicates that those built with high-grade materials last longer, even under harsh conditions.

Signal range and output options should not be overlooked. Some sensors provide analog outputs, while others offer digital signals. Depending on the application, having a choice can enhance system integration. Despite these options, it's common to find sensors that fall short in durability or ease of integration. Always check user reviews to understand the real-life performance of different models. Remember, even the best sensors require careful consideration for your specific needs.

Top 10 Split Core Current Sensors for Accurate Electrical Measurement

| Sensor Model |

Current Range (A) |

Accuracy (%) |

Output Type |

Response Time (ms) |

Price (USD) |

| Model A |

0-100 |

1.0 |

Voltage |

5 |

50 |

| Model B |

0-200 |

1.5 |

Current |

3 |

70 |

| Model C |

0-150 |

0.5 |

Voltage |

10 |

65 |

| Model D |

0-300 |

2.0 |

Current |

6 |

80 |

| Model E |

0-250 |

0.8 |

Voltage |

15 |

60 |

| Model F |

0-120 |

1.2 |

Current |

7 |

55 |

| Model G |

0-80 |

2.5 |

Voltage |

12 |

40 |

| Model H |

0-400 |

1.8 |

Current |

4 |

90 |

| Model I |

0-500 |

1.0 |

Voltage |

8 |

75 |

| Model J |

0-600 |

0.9 |

Current |

9 |

85 |

Comparison of Top 10 Split Core Current Sensors in the Market

When searching for split core current sensors, accuracy is key. Different models offer various features for electrical measurement. These sensors can differ in terms of sensitivity, range, and installation ease. Some may excel in specific applications while falling short in others.

It's important to compare the specifications closely. Look for sensors that have a wide sensing range and high accuracy. Pay attention to the output type, as some may provide analog signals while others offer digital outputs. Each sensor's design can impact installation, so consider if a model is easy to mount or requires more effort.

Many users find themselves unsure which sensor to choose. They often start with a list but get overwhelmed by choices. Reading user experiences can provide insight. This can lead to better decisions in selecting the right sensor for a specific need. In the end, finding the right split core current sensor may require more research and patience.

Evaluation of Accuracy and Performance Metrics in Current Sensors

The accuracy of current sensors is vital in electrical measurement. Many professionals rely on these devices for precise data. Reports indicate that up to 80% of industrial applications demand a high level of accuracy. This necessity highlights the growing importance in selecting the right split core current sensor. Factors such as measurement range, sensitivity, and temperature coefficient significantly impact performance.

Recent studies show that sensors with a lower total harmonic distortion (THD) can enhance accuracy. A THD of less than 1% typically yields reliable data for commercial applications. Notably, calibration practices affect longevity and reliability. Regular recalibration may be needed to maintain optimal performance. Interestingly, many devices fall short of expected standards over time. Inconsistencies can stem from environmental factors or component degradation.

End users must be mindful of these variations. Understanding the impact of usage conditions is critical. Sensor placement and installation practices also play a role in overall accuracy. Disregarding these details can lead to significant measurement errors. Regular assessments and adjustments can help mitigate these issues, ensuring that the selected sensor meets the necessary performance metrics.

Future Trends and Innovations in Split Core Current Sensor Technology

The future of split core current sensors is bright and full of innovations. Advances in technology could lead to sensors that are not only more accurate but also easier to install. Emerging wireless technologies may allow for remote monitoring capabilities. This would simplify data collection and improve overall efficiency in energy consumption.

Tips: Look for sensors that offer compatibility with existing systems. This ensures easy integration without costly upgrades.

Miniaturization is another trend. Smaller sensors can be deployed in more places. This opens up new possibilities for monitoring in tight spaces or on smaller devices. Enhanced data analytics could provide deeper insights. Users might access real-time data trends and historical usage patterns.

Tips: Prioritize sensors with advanced data processing capabilities. This can help convert raw data into actionable insights.

While innovation drives growth, it also brings challenges. Not all technologies may reach market readiness quickly. Some users may face issues during implementation. This highlights the need for effective training and support.

Tips: Seek support and resources from manufacturers or technology experts when adopting new sensors. This helps mitigate risks and ensures smoother transitions.

X

X

X

X  X

X  X

X