X

X - Products

- Solutions

- Support

- Contact

- Order Online

X

X - BACK

- Power Meters

- Control Panels

- Current Transformers

- BAS Sensors

- Communication Devices

- Energy Software

- Applications

- Resource Center

X

X - BACK

- All Power Meters

- Acuvim 3Power Quality Meter & Analyzer

- Acuvim II SeriesAdvanced Multifunction Power Meters

- Acuvim IIBNBACnet Power & Energy Meter

- Acuvim L SeriesMultifunction Energy Meters

- EV300 SeriesPower & Energy Panel Meters

- AcuRev 2100 SeriesMulti-Circuit Submeters

- AcuRev 2000 SeriesMulti-Channel Submeters

- AcuRev 1310 SeriesDIN-Rail 3-Phase Energy Meters

- AcuDC 300 SeriesEV Charging Meter

- AcuDC 240 SeriesDC Power & Energy Meters

- Tesla Power MetersTesla Power Meter Order Form

- All Communication Devices

- AcuHMIHMI & Gateway

- AcuLink 810DAQ Gateway & Server

- AcuMeshWireless Modbus-RTU Transceiver

- AXM-WEB2WiFi, Dual Ethernet Module

- AXM-WEB2 FOLCFiber Optics, WiFi, Ethernet Module

- AXM-WEB2-DDual Ethernet Module

- AcuDC 240 ModulesComm. Expansion for AcuDC 240 Meters

- All Pre-Wired Control Panels

- AcuPanel 9108X SeriesPre-Wired Control Panel for Acuvim 3 Power Quality Meter

- AcuPanel 9104XAcuPanel 9104X Pre-Wired Power Metering Control Panel

- AcuPanel 9106XAcuPanel 9106X Pre-Wired Multi-Channel Submetering Control Panel

- AcuPanel 9104X-DCAcuPanel 9104X-DC Pre-Wired DC Metering Control Panel

- UL 508A Panel ShopPre-Wired Custom Contol Panel

- AcuCloud Login

- AcuCloud EMSCloud-based Energy Management Solution

- Metering Data Collection

- Tenant Billing Software

- Energy Analysis & Reporting

- Utility Billing Software

- All Application Solutions

- DC Metering

- Energy Efficiency

- Metering

- Panel Metering

- Power Distribution

- Power Quality

X

X - BACK

- All Rogowski Coils

- AcuCT Flex SeriesFlexible Current Transformers

- RIK 1AR Flexible CTProtection Relay 1A Output

- RIK 5A Flexible CT5A Output Integrator

- RIK 333mV Flexible CT333mV Output Integrator

- RIK 4-20mA / 0-20mA CT4-20mA or 0-20mA Output Integrator

- RIK 0-5V / 0-10V CT0-5V or 0-10V Output Integrator

- All Split-Core CTs

- AcuCT R SeriesRevenue-Grade Split-Core CT

- AcuCT 5A Series5A Split-Core Current Transformers

- AcuCT mV Series333mV Split-Core CT

- AcuCT Hinged SeriesBranch Circuit 333mV CT

- All Solid-Core CTs

- AcuCT S77Revenue-Grade Solid-Core CT

- AcuCT S1135A Solid-Core Current Sensor

- AcuCT S125Solid-Core CT

- AcuCT S165Solid-Core CT

- AcuCT S220Switchgear Solid-Core CT

- AcuCT S335Busbar Solid-Core CT

- AcuCT S433Instrument Solid-Core CT

- AcuCT S650Solid-Core CT

- All DC Sensors

- HAB 16555DC Current Sensors

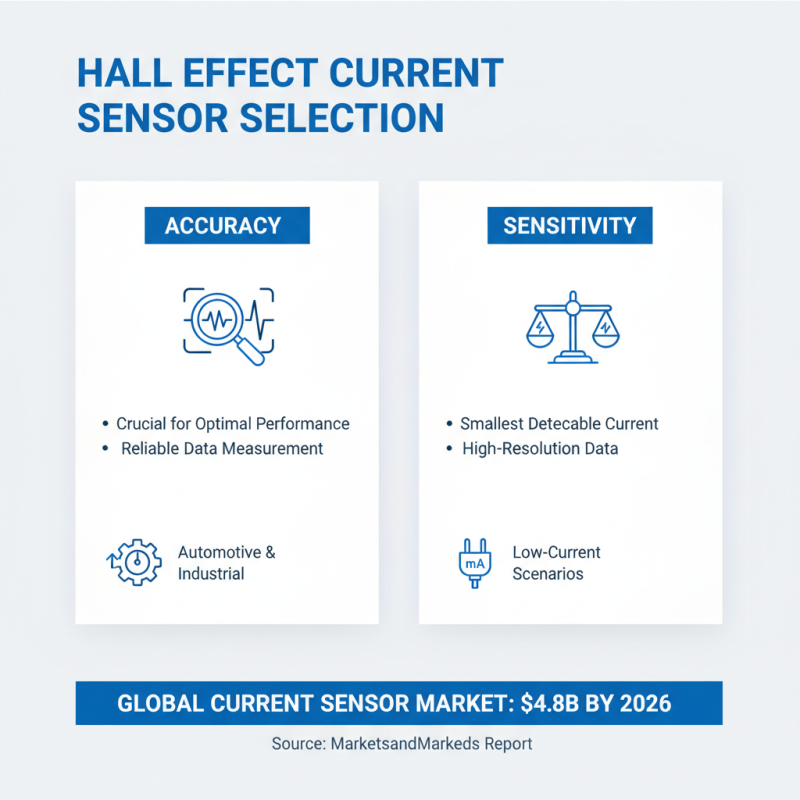

- HAK SeriesHall Effect Current Sensors

- DC Shunts0.1 - 0.5% Accuracy

- HV2DC High Voltage Sensor

- All CT Accessories

- RCT GRIP KitRogowski Mount Installation Kit

- AcuCT C5A to 80mA/100mA CT Converter

- All Differential Pressure Sensors

- AcuPRE DMDuct Mount Differential Pressure Sensor

- AcuPRE PMPanel Mount Differential Pressure Sensor

- AcuPRE WMWall Mount Differential Pressure Sensor

- All RH & Temperature Sensors

- AcuHUM DMDuct Mount RH Sensor

- AcuHUM RMRoom Mount RH Sensor

- AcuHUM OA/OAWOutdoor Air RH Sensor

- All Temperature Sensors

- AcuTEMS DMDuct Mount Temperature Sensors

- AcuTEMS IMImmersion Temperature Sensors

- AcuTEMS OAOutside Air Temperature Sensors

- AcuTEMS RMRoom Mount Temperature Sensors

- AcuTEMS WP304SS Wall Plate Temperature Sensors

- All DC Metering

- DC Circuit MonitoringDC Metering for Renewable Systems

- EV Charging StationsEnergy Metering for EV

- All Energy Efficiency

- Energy AuditsMetering Energy Audits

- Time-of-Use MeteringUnderstanding Peaks, Off-Peak Periods

- All Metering

- Tenant SubmeteringHow Tenant Submetering Works

- Branch Circuit MonitoringDense Circuit Metering Implementation

- HVAC MeteringHVAC Energy Management

- Remote MeteringRemote Metering and Monitoring

- kWh MeteringWhat is Kilowatt-Hour Metering