Why Choose Rogowski Coil Current Sensors for Accurate Current Measurement?

The Rogowski coil current sensor has emerged as a leading solution for accurate current measurement in various industrial applications, thanks to its unique design and operational advantages. According to a report by Grand View Research, the global current sensor market is anticipated to reach USD 3.6 billion by 2025, driven by the increasing demand for precision measurement instruments in sectors such as automotive, industrial automation, and renewable energy. The Rogowski coil, with its flexible and non-intrusive nature, allows for effortless integration and installation in tight spaces, a feature that is increasingly essential as systems grow more compact.

One of the primary reasons for adopting Rogowski coil current sensors is their remarkable accuracy in measuring alternating current (AC) over a wide frequency range. Research by the Institute of Electrical and Electronics Engineers (IEEE) highlights how traditional current measurement techniques often struggle with precision, especially in dynamic environments where the load characteristics vary rapidly. The Rogowski coil’s ability to maintain accuracy under these conditions, coupled with its minimal impact on the circuit being measured, makes it an invaluable tool for engineers and technicians seeking reliable and immediate data for their applications. As industries continue to embrace smart technologies and strive for higher efficiency, the role of Rogowski coil current sensors will undoubtedly expand, setting new standards in current measurement practices.

The Principles of Rogowski Coil Operation in Current Measurement

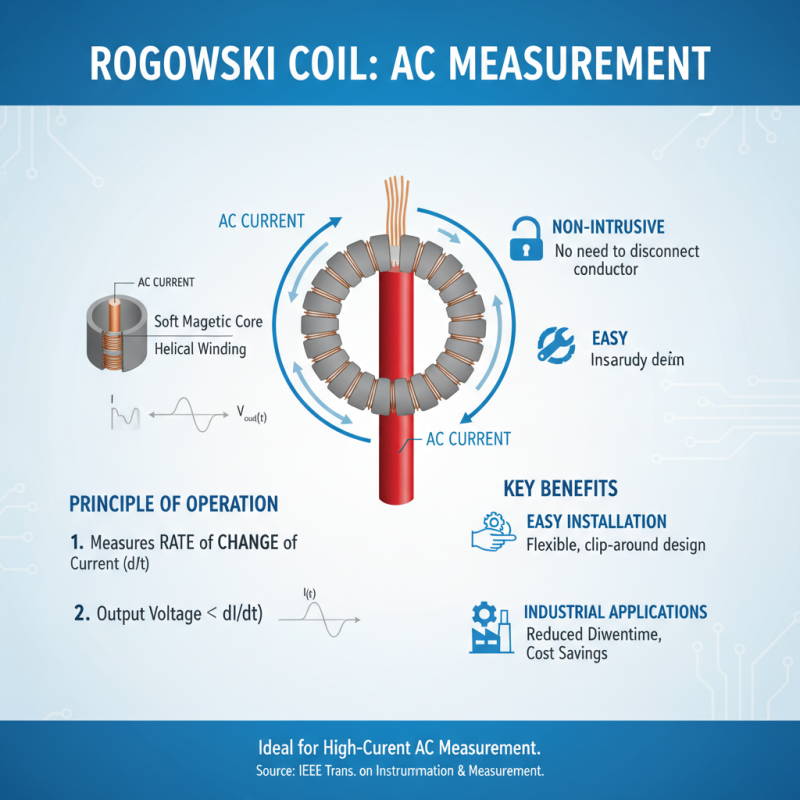

The Rogowski coil is a highly effective solution for measuring alternating current (AC) due to its fundamental principles of operation. It consists of a soft magnetic core wound with a helical wire, which creates a voltage proportional to the rate of change of current flowing through a conductor. This design allows for a non-intrusive method of current measurement, eliminating the need to disconnect the conductor. According to the IEEE Transactions on Instrumentation and Measurement, this non-invasive capability is critical in industrial applications where downtime for installation can result in significant costs.

Moreover, the Rogowski coil's wide frequency response—from DC to several hundred kHz—makes it versatile for various applications, including power quality monitoring and load profiling. A study published in the Journal of Electrical Engineering and Technology highlighted that Rogowski coils can achieve measurement uncertainties as low as 1%, making them suitable for high-precision applications in renewable energy systems and smart grids. This accuracy surpasses traditional current transformers, particularly in environments with high-frequency transients, underscoring the increasing preference for Rogowski coils in modern electrical measurement practices.

With their lightweight design and ability to measure large currents safely, Rogowski coils are gaining traction in both research and industrial settings. The global demand for accurate and real-time current measurement technologies, as reported by industry analysts, is expected to drive innovations in sensor technologies, with Rogowski coils at the forefront of this trend.

Advantages of Rogowski Coils Over Traditional Current Sensors

Rogowski coil current sensors offer several advantages over traditional current measurement methods, making them an ideal choice for accurate and reliable current measurement in various applications. One of the primary benefits of Rogowski coils is their non-intrusive nature. Unlike clamp meters or shunt resistors that require direct contact with the conductors, Rogowski coils can be placed around an electromagnetic conductor without interrupting the circuit. This feature not only simplifies installation but also minimizes the risk of circuit disturbances or equipment damage.

Another significant advantage of Rogowski coils is their linear response over a wide range of currents. They effectively handle both high and low current measurements with exceptional accuracy, unlike traditional Hall effect sensors or current transformers that may struggle at the extremes of their measurement range. Additionally, Rogowski coils are lightweight and flexible, allowing them to be easily wrapped around conductors of various shapes and sizes. This versatility makes them particularly useful in crowded electrical panels or confined installation spaces. Overall, these characteristics make Rogowski coil current sensors a superior choice for achieving precise current measurements in diverse electrical and industrial applications.

Advantages of Rogowski Coil Current Sensors Over Traditional Current Sensors

This chart compares the advantages of Rogowski coil current sensors against traditional current sensors across different performance metrics.

Accuracy Levels of Rogowski Coils Compared to Hall Effect Sensors

Rogowski coil current sensors are increasingly favored for their superior accuracy in current measurement, particularly when compared to traditional Hall effect sensors. One of the primary advantages of Rogowski coils is their ability to measure alternating current (AC) across a wide frequency range without the need for a ferromagnetic core. This design feature allows for minimal saturation effects and enhanced linearity, leading to highly accurate readings even in environments with fluctuating current levels. In contrast, Hall effect sensors may struggle with precision at higher frequencies, as their performance can degrade due to core material limitations.

Furthermore, Rogowski coils offer several inherent advantages that contribute to their accuracy levels. Unlike Hall effect sensors, which rely on the magnetic field generated by the current passing through a conductor, Rogowski coils operate based on the principle of inductive coupling. This results in a more stable output throughout the measurement range. Additionally, Rogowski coils are less susceptible to external interference and noise, ensuring that their readings remain reliable under various operational conditions. This makes them an ideal choice for applications requiring precise current measurements, such as in power systems and industrial automation.

Applications of Rogowski Coil Sensors in Industrial Settings

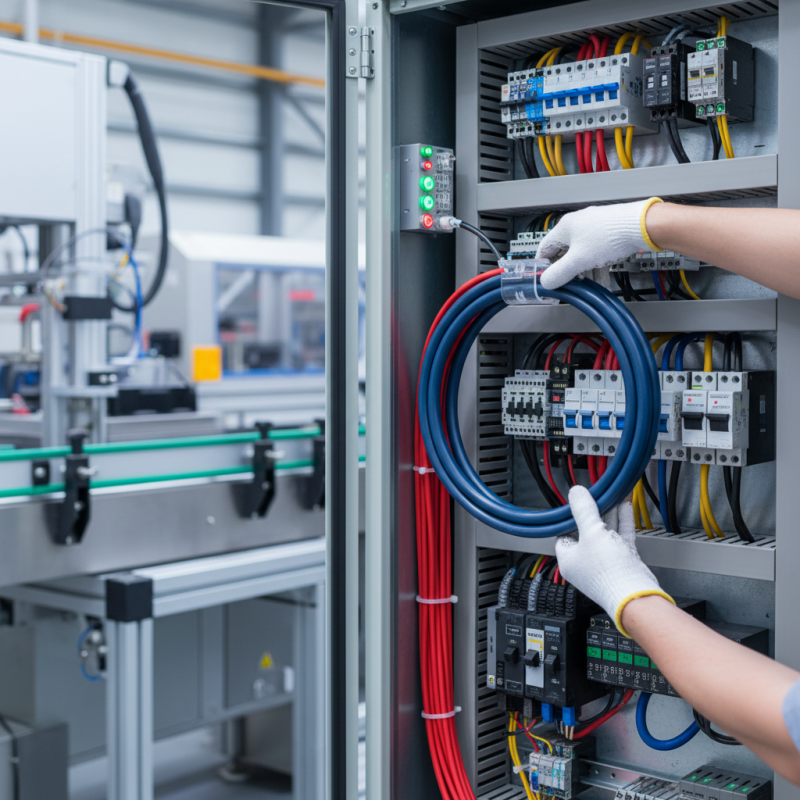

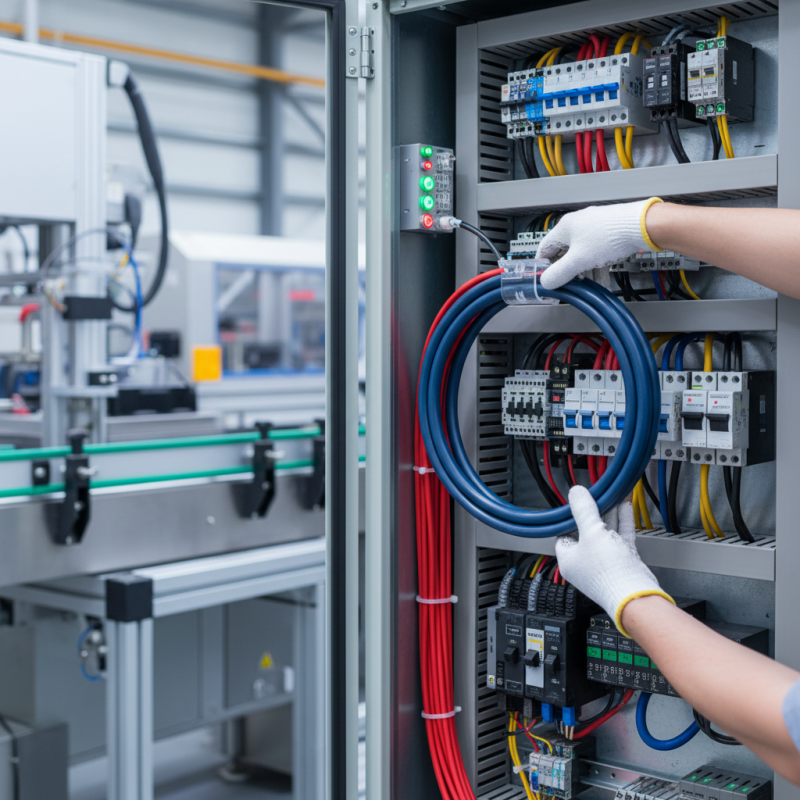

Rogowski coil current sensors have emerged as a preferred choice for accurate current measurement in various industrial applications. Their non-invasive design allows for easy integration into existing systems without the need for complex modifications. These sensors excel in high-frequency current measurements, making them ideal for environments where precise monitoring of electrical currents is crucial. Their ability to handle large and fluctuating currents without saturation means they can be reliably used in critical applications such as motor drive systems and power distribution networks.

In industries like manufacturing, energy generation, and renewable energy, Rogowski coils are employed for real-time monitoring of machinery and electrical equipment. Their flexibility and lightweight nature make them suitable for installation in confined spaces or around large conductors. Moreover, these sensors facilitate the implementation of predictive maintenance strategies by providing accurate data on current trends, helping to prevent equipment failures and ensuring operational efficiency. As industries increasingly strive for smarter and more responsive solutions, the adoption of Rogowski coil sensors is likely to rise, reinforcing their role as a vital tool in modern industrial settings.

Why Choose Rogowski Coil Current Sensors for Accurate Current Measurement? - Applications of Rogowski Coil Sensors in Industrial Settings

| Application Area |

Current Range (A) |

Measurement Accuracy |

Sensitivity (V/A) |

Frequency Range (Hz) |

| Power Generation |

0-5000 |

±1% |

0.05 |

0-1000 |

| Industrial Automation |

0-2000 |

±0.5% |

0.1 |

0-2000 |

| HVAC Systems |

0-1000 |

±2% |

0.05 |

0-500 |

| Renewable Energy |

0-3000 |

±1% |

0.07 |

0-1000 |

| Electric Transportation |

0-1500 |

±1.5% |

0.1 |

0-2000 |

Recent Innovations and Future Trends in Rogowski Coil Technology

Recent advancements in Rogowski coil technology have led to significant improvements in current measurement accuracy, flexibility, and application scope. These non-intrusive sensors are now designed to handle a wider range of current levels, making them suitable for industrial use, renewable energy applications, and electric vehicles. Innovations such as enhanced materials for better sensitivity and signal integrity have transformed conventional designs into high-tech devices capable of real-time data acquisition and analysis. Moreover, with the integration of digital signal processing, these coils can now provide more precise measurements while minimizing noise.

Tips: When selecting a Rogowski coil for your application, consider factors such as bandwidth, sensitivity, and environmental conditions. Ensure that the coil you choose can adapt to the specific range of currents you need to measure. Additionally, always check for compatibility with your existing measurement systems to optimize performance.

Future trends suggest that the evolution of Rogowski coils will continue, particularly with the incorporation of advanced technologies like IoT and artificial intelligence. This will enable remote monitoring capabilities and predictive maintenance, ensuring that systems can run more efficiently and reliably. As these sensors evolve, they promise to play a crucial role in the transition towards smarter energy systems and optimized industrial processes.

X

X

X

X  X

X  X

X