How to Read a Three Phase Meter for Accurate Energy Monitoring

In the realm of energy management, understanding the intricacies of a three phase meter is crucial for accurate consumption tracking and optimization. Energy specialists emphasize the importance of proficiency in reading these meters to enable effective monitoring and reduction of energy costs. Dr. Emily Thompson, an expert in energy systems, once stated, "Mastering the reading of a three phase meter is essential for anyone looking to enhance their energy efficiency." This assertion highlights the increasing reliance on three phase systems in both industrial and commercial settings.

Three phase meters are designed to measure the electrical energy consumption of industrial loads, offering a more balanced and efficient alternative to single-phase meters. With the increasing complexity of energy usage in modern facilities, mastering the operation and reading of a three phase meter can significantly impact energy management strategies. Understanding how to interpret the readings from these meters not only aids in tracking usage but also plays a critical role in planning for future energy needs, reducing operational costs, and ensuring compliance with energy regulations.

As we delve into the methods of reading a three phase meter, it is essential to recognize the significance of accurate data collection and analysis. Whether for optimizing energy efficiency or strategizing for sustainability, the insights gained from a well-read three phase meter can empower businesses to make informed decisions that contribute to their overall energy goals.

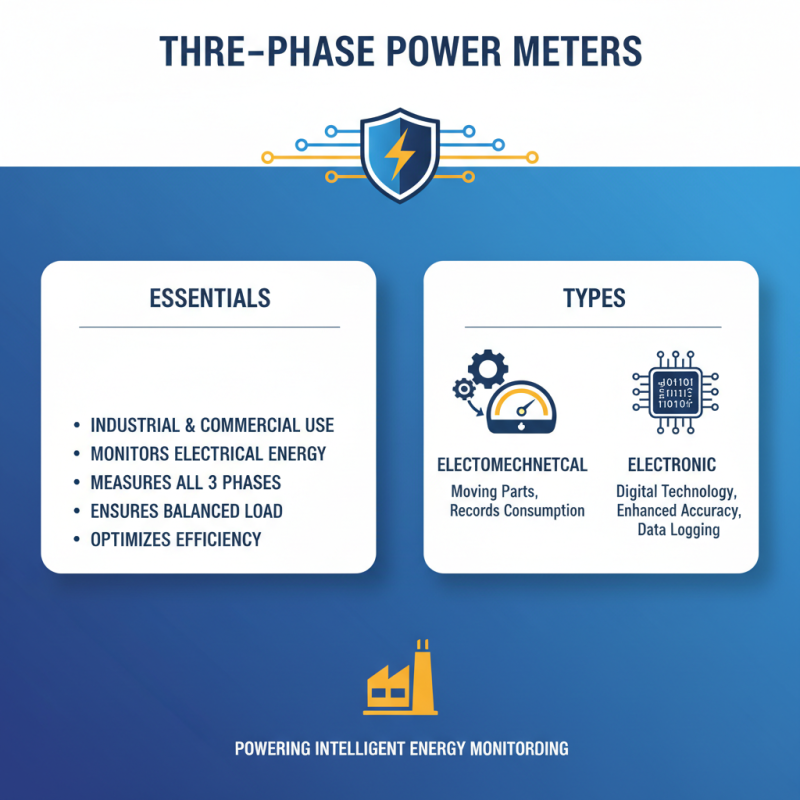

Understanding Three Phase Meters: Types and Functions

Three-phase meters are essential instruments used for monitoring electrical energy consumption in industrial and commercial settings. These meters provide a comprehensive overview of electricity usage by measuring the energy in each of the three phases of power supply, ensuring a balanced load and optimizing the efficiency of electrical systems. The most common types of three-phase meters include electromechanical meters, which utilize moving parts to record energy consumption, and electronic meters that employ digital technology to offer enhanced accuracy and data logging capabilities.

Research from the International Energy Agency (IEA) highlights that approximately 30% of energy losses in industrial processes are due to inefficient electrical systems. Implementing three-phase metering can significantly mitigate these losses by providing businesses with vital insights into their energy usage patterns. By understanding the load distribution across the three phases, users can identify imbalances that could lead to equipment overheating and increased operational costs. Furthermore, regular monitoring through three-phase meters enables informed decision-making to improve energy efficiency, ultimately contributing to reduced operational expenses and lower carbon footprints in line with global sustainability goals.

Components of a Three Phase Meter: What You Need to Know

A three-phase meter is an essential tool for accurately monitoring energy consumption in industrial and commercial settings. Understanding its components is crucial for effective usage. Typically, a three-phase meter consists of a current transformer, a voltage transformer, and measurement circuitry that collectively provide insights into energy usage. According to the U.S. Energy Information Administration, three-phase systems account for approximately 75% of the total energy consumption in commercial environments due to their efficiency in power distribution.

The current transformer is responsible for measuring the current flowing through the wires, while the voltage transformer ensures that voltage levels are suitable for accurate reading. Together, these components allow for the calculation of real, reactive, and apparent power, which are vital for energy management. In fact, the International Energy Agency notes that proper monitoring can lead to energy savings of 10-20% in large facilities.

Tips for Using a Three-Phase Meter: Regularly check the calibration of your meter to ensure accuracy. Utilize software tools that integrate with your meter for real-time data analysis, enabling better decision-making. Lastly, familiarize yourself with the readings of the meter to interpret data effectively, allowing for preventative maintenance and reduction of energy waste.

Steps to Read a Three Phase Meter: A Practical Guide

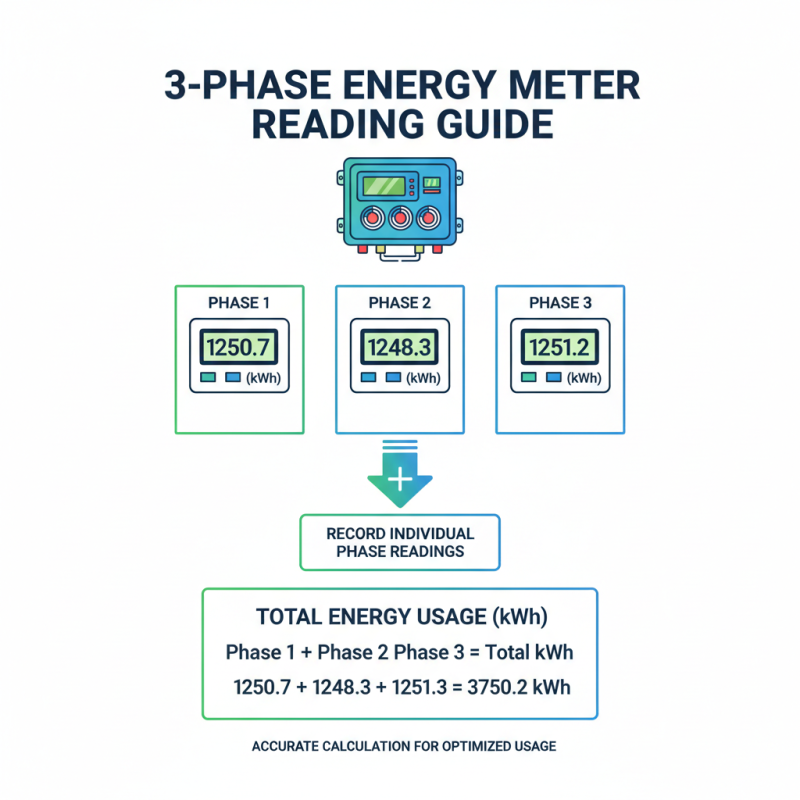

To read a three-phase meter accurately, it's essential to understand the layout and display of the meter itself. Typically, a three-phase meter will have three main dials or digital displays, each corresponding to one phase of electricity. Start by identifying the phases, usually labeled A, B, and C. If the meter has analog dials, take note of the position of the needle for each dial, as each dial measures the energy consumed in kilowatt-hours (kWh). For digital meters, simply read the numerical display for each phase and note the values.

Once you have recorded the readings for all three phases, calculate the total energy consumed by adding the values together. This total will give you a comprehensive view of energy usage across the three phases, which is crucial for efficient monitoring and management of energy consumption. It is also advisable to regularly take these readings at the same time intervals—for instance, weekly or monthly—to track usage trends over time. This practice can help in identifying peak usage times and making informed decisions regarding energy efficiency improvements.

Calculating Energy Usage: Interpreting the Readings

To accurately calculate energy usage from a three-phase meter, it's essential to understand how to interpret the readings displayed on the meter. A three-phase meter typically has three current coils, corresponding to each phase of the electrical system, along with voltage measurement components. When you observe the meter readings, you will notice multiple dials or digital displays, each representing the kilowatt-hours (kWh) consumed by each phase. It's crucial to record these values carefully, as they directly impact your energy usage calculations.

To determine the total energy consumption, you'll need to sum the readings from all three phases. If the meter displays readings in kilowatt-hours, simply add the values of each phase together to get the overall energy usage. For example, if the readings show 150 kWh, 160 kWh, and 140 kWh for phases A, B, and C respectively, your total energy usage would be 450 kWh. Monitoring these readings regularly can help track energy trends and identify irregularities that may indicate electrical issues or inefficiencies within your systems. Understanding how to interpret these readings is key to effective energy management and resource allocation.

Tips for Accurate Energy Monitoring with Three Phase Meters

Three phase meters are crucial for monitoring energy consumption in industrial and commercial applications, as they provide a comprehensive view of electrical usage across multiple phases. According to a report by the International Energy Agency, efficient monitoring of energy usage can reduce operational costs by up to 20%. This highlights the importance of using three phase meters effectively to ensure accurate readings and better energy management.

To enhance the accuracy of energy monitoring with three phase meters, here are some essential tips: First, ensure that the meter is properly installed and calibrated. Misalignment or improper connections can lead to faulty readings. Additionally, regularly comparing meter readings against expected usage patterns can help identify any discrepancies. Keeping a log of readings will also aid in tracking energy consumption trends over time, allowing for more informed decisions related to energy efficiency.

Finally, consider implementing advanced monitoring systems that integrate data from three phase meters with energy management software. This can automate the data collection process and provide real-time insights into energy usage, enabling organizations to take proactive measures in reducing waste and optimizing their energy consumption strategies.

How to Read a Three Phase Meter for Accurate Energy Monitoring

| Phase |

Voltage (V) |

Current (A) |

Power Factor |

Active Power (kW) |

Reactive Power (kVAR) |

Energy Consumed (kWh) |

| Phase 1 |

400 |

10 |

0.9 |

4.0 |

1.5 |

1000 |

| Phase 2 |

400 |

15 |

0.85 |

5.1 |

1.9 |

1200 |

| Phase 3 |

400 |

12 |

0.95 |

3.6 |

1.0 |

1100 |

X

X

X

X  X

X  X

X