What is a DC Current Transducer and How Does It Work?

In the realm of electrical engineering, the understanding of DC current transducers has become essential for accurately measuring and monitoring direct current in various applications. As indicated by Dr. Jane Smith, a renowned expert in the field of electrical measurement technology, "The accuracy and reliability of a DC current transducer are paramount for the safety and efficiency of electrical systems." This statement encapsulates the vital role that DC current transducers play in different sectors, from industrial automation to renewable energy systems.

DC current transducers operate by converting the direct current flowing through a conductor into a proportional voltage or current signal, allowing for effective monitoring and control. Their design and operational principles are based on advanced electromagnetic or Hall-effect technologies, which ensure precise readings even in challenging environments. As electrical systems continue to evolve, the integration of high-performance DC current transducers is crucial for the development of smart grids and efficient power management solutions. By understanding how these devices work, engineers can enhance system designs and improve overall performance, ultimately fostering a more sustainable energy future.

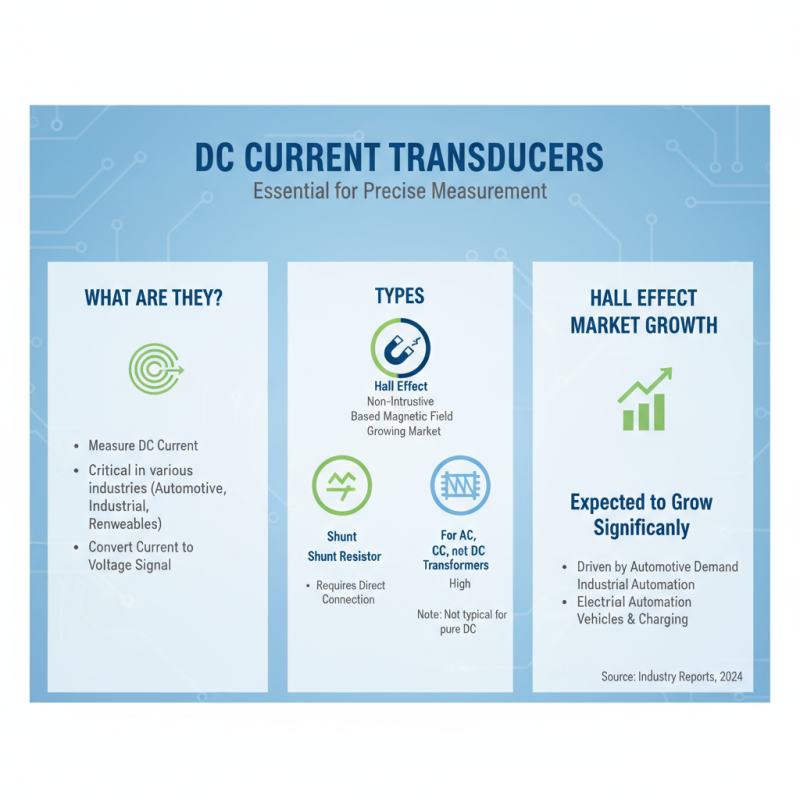

What is a DC Current Transducer?

A DC current transducer is an essential device used to measure direct current (DC) in various applications, such as industrial automation, power monitoring, and renewable energy systems. It operates by converting the DC current flowing through a conductor into a proportional voltage or current signal that can be easily read and processed by monitoring equipment. This conversion is crucial for ensuring accurate measurement and control in electrical systems, allowing for real-time monitoring and data analysis.

The working principle of a DC current transducer typically involves the use of a shunt resistor or Hall effect sensor. When a DC current passes through the shunt resistor, a small voltage drop is generated proportional to the current, following Ohm's law. Alternatively, a Hall effect sensor detects the magnetic field produced by the current, translating it into a corresponding electrical signal. These signals can then be transmitted to a control system or display, enabling users to monitor current levels, detect faults, and maintain efficient system operations. Overall, DC current transducers play a pivotal role in ensuring safe and effective management of electrical energy.

DC Current Measurement Data

Principle of Operation of DC Current Transducers

DC current transducers are essential devices used to measure direct current (DC) flowing through a circuit. The principle of operation of these transducers is based on the interaction between electrical and magnetic fields. When a direct current passes through a conductive element, it generates a magnetic field proportional to the magnitude of the current. The transducer leverages this phenomenon to produce an output voltage that corresponds to the input current.

Typically, a DC current transducer employs a Hall effect sensor or a current shunt to detect the magnetic field or measure the voltage drop across a known resistor, respectively. In the case of the Hall effect sensor, it generates a voltage signal when placed in a magnetic field due to the movement of charge carriers. This output can be calibrated to reflect the actual current value. On the other hand, current shunts convert the current flow into a measurable voltage, providing a linear relationship between input current and output voltage.

The accuracy and responsiveness of these transducers are critical for various applications, including industrial monitoring, power management, and circuit protection, facilitating essential feedback mechanisms in electrical systems.

Types of DC Current Transducers and Their Applications

DC current transducers are essential components in various industries where precise current measurement is critical. They can be categorized into several types, including Hall effect transducers, shunt resistor-based transducers, and current transformers. Hall effect transducers utilize the magnetic field generated by the current flow to produce a proportional output voltage, making them effective for non-intrusive measurements. According to recent industry reports, the Hall effect transducer market is expected to grow significantly, driven by increasing demand in automotive and industrial applications.

Shunt resistor-based transducers are widely used for their simplicity and accuracy. They work by measuring the voltage drop across a precision resistor placed in series with the load, allowing for direct current measurement with minimal impact on the circuit's performance. This type of transducer is often favored in renewable energy applications, where monitoring of DC currents from solar panels and wind turbines is essential. Reports indicate that the renewable energy sector will continue to expand, projected to reach a market size of over $1.5 trillion by 2025, further driving the adoption of reliable DC current measurement solutions.

Current transformers, while typically associated with AC measurements, are adapted for use in DC applications, particularly in high-voltage power systems. These transducers are crucial for monitoring and protecting electrical equipment by providing accurate current readings that facilitate better management of power resources. The rise in the global energy demand is expected to increase the deployment of such transducers, as outlined in market analyses, which predict substantial growth in smart grid technologies and electrical infrastructure enhancements.

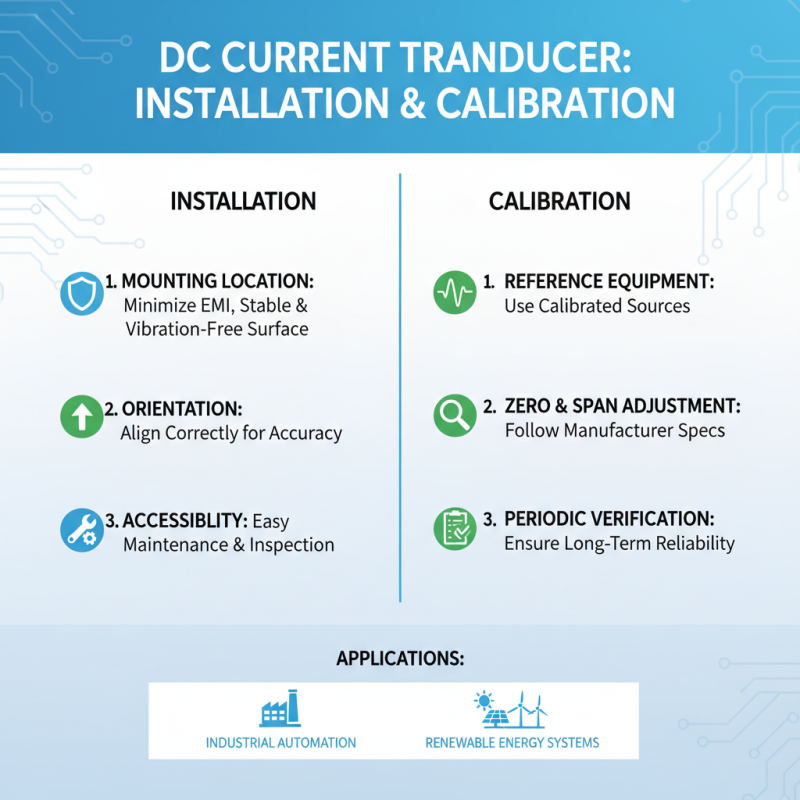

Installation and Calibration Process for DC Current Transducers

The installation and calibration of DC current transducers are critical steps to ensure accurate measurement and reliability in various applications, including industrial automation and renewable energy systems. Proper installation involves selecting an appropriate mounting location that minimizes electromagnetic interference and allows for easy access for maintenance. According to industry standards, the mounting surface should be stable and free from vibrations to maintain measurement integrity. Ensuring that the current transducer is correctly oriented is essential, as misalignment could lead to significant measurement errors.

Once the transducer is installed, calibration is vital for precision. The calibration process typically involves applying known current values and adjusting the transducer output to match these values within specified tolerances. Industry reports, such as those from the International Electrotechnical Commission (IEC), suggest that transducers should be calibrated under the actual environmental conditions they will experience in operation, including temperature and humidity levels. Calibration should be performed regularly, with many experts recommending intervals of six to twelve months to maintain accuracy. Calibration records should also be kept in compliance with ISO standards to facilitate quality assurance and traceability in measurement systems.

Advantages and Limitations of Using DC Current Transducers

DC current transducers are widely utilized in various applications due to their ability to measure current accurately in direct current systems. One of the primary advantages of using DC current transducers is their high precision and reliability. They provide real-time monitoring of electrical currents, making them essential for industrial automation, renewable energy systems, and electric vehicles. Additionally, these transducers can operate under a wide range of temperatures and environmental conditions, which adds to their versatility in different settings.

However, there are also limitations to consider. One significant drawback is their potential cost, as high-precision transducers can be more expensive than alternative measuring devices. Furthermore, while they are excellent for measuring stable DC currents, their performance may be less reliable for rapidly fluctuating currents or in situations where noise can affect readings. Additionally, installation and calibration may require specialized knowledge and equipment, which can complicate their integration into existing systems. Thus, while DC current transducers offer valuable benefits, it is crucial to weigh these advantages against their limitations when considering their application.

What is a DC Current Transducer and How Does It Work? - Advantages and Limitations of Using DC Current Transducers

| Feature |

Description |

| Working Principle |

DC current transducers convert direct current (DC) values into proportional output signals, typically voltage or current. |

| Types |

Hall Effect, Shunt Resistor, and Rogowski Coil transducers are common types used for measuring DC currents. |

| Advantages |

High accuracy, wide measurement range, ability to isolate circuits, and fast response time. |

| Limitations |

Cost may be higher than other measurement methods, limited by temperature variations, and complexity in installation for certain types. |

| Applications |

Used in power monitoring, renewable energy systems, and industrial automation for effective current measurement. |

X

X

X

X  X

X  X

X