Top 10 Tips for Choosing Hall Effect DC Current Sensors Effectively

In the rapidly evolving field of electronics, the selection of the right components is crucial for optimal performance and efficiency. One such essential component is the Hall Effect DC Current Sensor, renowned for its ability to provide accurate and reliable current measurements in various applications. According to Dr. Emily Johnson, a leading expert in sensor technology, “The choice of a Hall Effect DC Current Sensor can profoundly impact the reliability of your circuit designs and the overall functionality of your systems.”

Understanding the key factors that contribute to selecting the most effective Hall Effect DC Current Sensor can empower engineers and designers to make informed decisions. With a myriad of options available, it is critical to consider parameters such as measurement range, accuracy, response time, and the specific application requirements. This comprehensive guide aims to highlight the top ten tips for effectively choosing Hall Effect DC Current Sensors, equipping professionals with the knowledge needed to enhance their projects while ensuring safety and reliability.

Understanding Hall Effect DC Current Sensors and Their Applications

Hall Effect DC Current Sensors have gained significant traction in various applications, ranging from industrial automation to renewable energy systems. These sensors leverage the Hall effect principle, which allows them to detect magnetic fields and convert them into corresponding voltage signals. According to a recent market report, the global Hall effect sensor market is projected to reach $4.7 billion by 2025, driven by the rising adoption of automated systems and electric vehicles. This underscores the growing importance of selecting the right sensor for specific needs.

In industrial applications, the ability to accurately measure DC current is crucial for energy management and equipment protection. Hall Effect sensors offer non-intrusive measurements, meaning they can monitor current without needing to physically isolate the circuit being measured. This characteristic not only provides safety benefits but also enhances the longevity of the sensors themselves. Reports indicate that industries using Hall effect sensors experience up to a 30% reduction in failure rates related to current measurement inaccuracies, highlighting the effectiveness of these devices in critical applications.

Furthermore, the versatility of Hall Effect DC Current Sensors extends to renewable energy setups like solar inverters and wind turbines. Their capability to handle a wide range of current levels and their robustness against environmental factors make them ideal for these applications. Research indicates that integrating advanced sensor technologies can improve the efficiency of energy conversion by approximately 15%, further illustrating the vital role these sensors play in modern energy systems. As the demand for precision in current measurement continues to rise, understanding the various applications and benefits of Hall Effect sensors is essential for effective implementation.

Current Measurement in Hall Effect DC Current Sensors

Key Specifications to Consider When Selecting Current Sensors

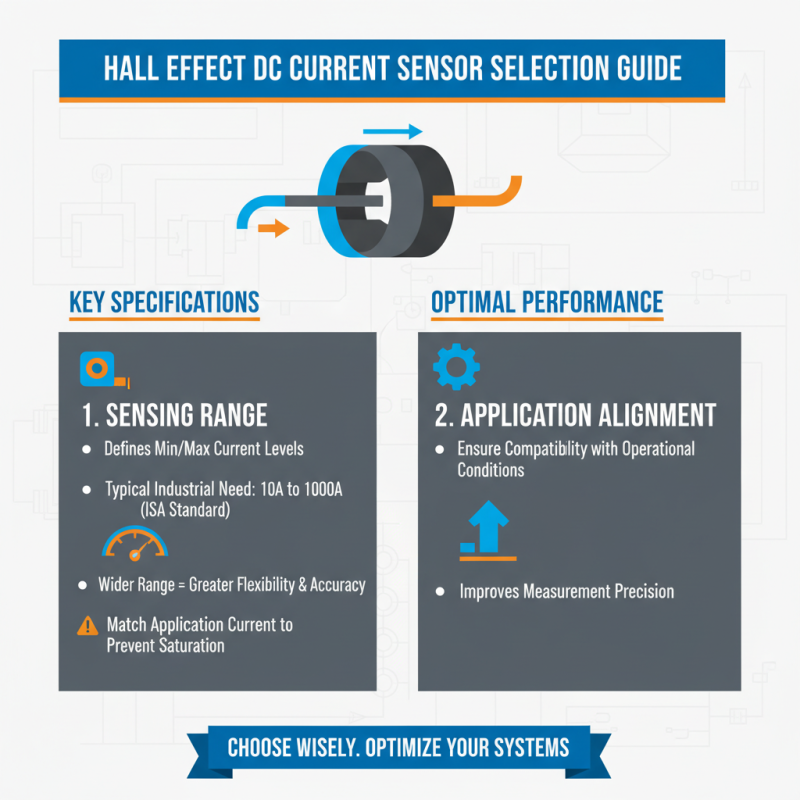

When selecting Hall Effect DC current sensors, key specifications play a crucial role in ensuring optimal performance for various applications. One of the primary specifications to consider is the sensing range, which dictates the maximum and minimum current levels the sensor can measure. According to the International Society of Automation (ISA), sensors typically need to cover a range of 10 A to 1000 A, where a broader sensing range allows for greater flexibility across different operational conditions. It’s essential to choose a sensor whose range aligns with the specific current levels encountered in your application to maintain accuracy and prevent saturation.

Another important specification is the output type and linearity. Many Hall Effect sensors provide either analog or digital outputs, each suitable for different applications. For instance, analog outputs can facilitate a continuous measurement throughout the sensor’s working range, while digital outputs may simplify integration into microcontroller systems. The linearity of the sensor also affects its accuracy; high linearity ensures that the sensor output correlates closely with actual current measurements. As reported by the IEEE, achieving linearity within ±1% of full scale is a standard benchmark for high-quality sensors, which is vital for applications requiring precise current monitoring. Selecting a Hall Effect sensor with vetted specifications can significantly enhance system reliability and efficiency.

Comparative Analysis of Hall Effect Sensors vs. Other Technologies

When evaluating Hall Effect DC current sensors compared to other technologies, it's essential to consider key performance parameters such as accuracy, sensitivity, and temperature stability. Hall Effect sensors generally exhibit excellent linearity and can operate over a wide range of temperatures, making them suitable for various demanding applications, from automotive systems to industrial automation. A recent industry report indicates that Hall Effect sensors can achieve measurement accuracies of up to 1%, significantly outperforming traditional shunt resistor-based measurements under varying thermal conditions.

When selecting a Hall Effect sensor, consider the following tips: first, assess the current range and ensure the sensor can accommodate the maximum expected load. Second, evaluate the sensor's sensitivity and resolution to ensure it can detect subtle changes in current. Finally, analyze the sensor's response time, as faster reaction times can be critical for real-time applications.

Another consideration is the mounting and installation requirements of the sensors. While many Hall Effect sensors are non-intrusive and can be mounted without interrupting the current path, other technologies such as Rogowski coils may require specific installation conditions that could complicate integration into existing systems. A comprehensive analysis of these installation factors can lead to improved system performance and reduced long-term operational costs.

Installation and Calibration Tips for Optimal Sensor Performance

When it comes to installing Hall Effect DC current sensors, proper placement is crucial for accurate readings. Ensure that the sensor is positioned close to the conductor, minimizing any potential interference from surrounding electrical components. Additionally, it's important to mount the sensor in a location that allows for easy access during calibration. Choose a surface that can accommodate the sensor's specifications while also providing protection from environmental factors that could affect its performance.

Calibration is another vital aspect that can significantly enhance sensor performance. After installation, it’s essential to calibrate the sensor according to the manufacturer's guidelines. Use a known current source for testing, which allows for precise adjustments. Pay attention to temperature variations during calibration, as these can impact the sensor's accuracy. Regular recalibration should also be part of your maintenance routine, ensuring that the sensor continues to deliver reliable readings over time.

Proper installation and calibration work hand in hand to maximize the efficacy of Hall Effect DC current sensors, ultimately leading to improved system performance.

Common Applications and Industry Use Cases for Hall Effect Sensors

Hall effect sensors are pivotal in various industries due to their ability to measure DC current without direct electrical contact. Common applications can be found in automotive systems, renewable energy, and industrial automation. For instance, in electric vehicles, Hall effect sensors monitor battery currents to optimize performance and ensure safety, enabling effective power management and enhancing the driving experience. According to reports by leading industry analysts, the market for Hall effect sensors in automotive applications is expected to grow at a CAGR of 6.3% over the next five years, driven by the increasing demand for electric and hybrid vehicles.

When selecting Hall effect DC current sensors, it's crucial to consider the environmental conditions in which they will operate. Sensors may be exposed to extreme temperatures or electromagnetic interference, which can affect their performance. Therefore, checking sensor ratings for environmental robustness should be a priority. In addition, carefully evaluating the sensor's sensitivity and output characteristics can further enhance measurement accuracy in critical applications.

Another important consideration is the integration of the sensor with existing systems. Ensuring compatibility with the current system architecture will facilitate smoother implementation and reduce downtime. According to recent studies, improper sensor selection can lead to substantial operational inefficiencies, underscoring the need for a comprehensive understanding of specific application requirements during the selection process. Minimize risks by consulting technical documentation and specifications before finalizing a sensor choice.

Top 10 Tips for Choosing Hall Effect DC Current Sensors Effectively

| Tip No. |

Tip Description |

Common Applications |

Industry Use Cases |

| 1 |

Determine the current range requirements. |

Electric Vehicles |

Motor Control |

| 2 |

Select the appropriate sensor topology (open-loop vs closed-loop). |

Renewable Energy |

Solar Inverters |

| 3 |

Consider the sensor's bandwidth and response time. |

Industrial Automation |

Robotics |

| 4 |

Evaluate thermal performance and heat dissipation. |

Power Supply Units |

Telecommunications |

| 5 |

Look for built-in isolation features. |

HVAC Systems |

Home Automation |

| 6 |

Check for linearity and accuracy specifications. |

Battery Management Systems |

Electric Mobility |

| 7 |

Analyze the sensor's size and mounting options. |

Consumer Electronics |

Wearable Technology |

| 8 |

Assess environmental resistance and ruggedness. |

Agricultural Equipment |

Farm Automation |

| 9 |

Ensure compliance with safety and regulatory standards. |

Medical Devices |

Patient Monitoring |

| 10 |

Consult with suppliers for application-specific recommendations. |

Smart Grids |

Energy Management |

X

X

X

X  X

X  X

X