2026 How to Choose the Right DC Current Sensor for Your Applications?

Choosing the right DC current sensor is crucial for multiple applications, from renewable energy systems to industrial automation. According to a recent market analysis by Grand View Research, the global DC current sensor market is projected to reach $1.0 billion by 2027, showing a steady growth rate. This indicates a rising demand for accurate and reliable sensing technologies.

Industry expert Dr. Emily Carter states, “The effectiveness of a DC current sensor can greatly affect overall system performance.” This highlights how essential it is to understand your application’s needs to select the best sensor. Many engineers struggle with this decision, often underestimating parameters like measurement range, response time, and environmental conditions.

An optimal sensor not only enhances application efficiency but also reduces downtime and maintenance costs. It's essential to re-evaluate the chosen sensor as technology evolves. Many products on the market may not align with new specifications, leading to performance issues. Continuous reflection on current needs is key to achieving the best results in the ever-changing landscape of DC current technology.

Understanding the Basics of DC Current Sensors and Their Functionality

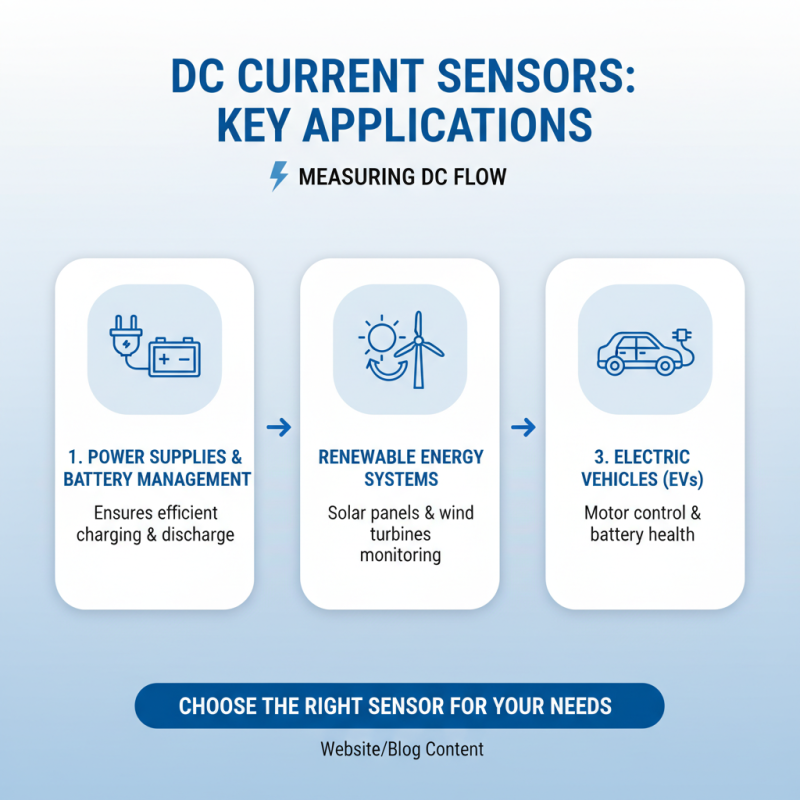

DC current sensors play a crucial role in various applications. They measure the flow of direct current in a circuit. Understanding their functionality is important for selecting the appropriate sensor for your needs. These sensors can be used in power supplies, renewable energy systems, and electric vehicles. Each application may require a different type of sensor.

There are several types of DC current sensors available. Hall effect sensors are quite popular. They can provide isolation and are suitable for higher currents. Shunt resistors offer accuracy but may lead to power loss. Some people overlook the impact of sensor placement. Improper positioning can affect accuracy.

Choosing the right sensor is not always straightforward. You need to consider factors like current range and sensor type. Additional features, such as temperature compensation, may be essential. However, these features also increase complexity. A balance must be struck between functionality and ease of integration. Remember that testing is key. The ideal sensor should be reliable under different conditions.

Types of DC Current Sensors and Their Specific Applications

DC current sensors come in various types, each designed for specific applications. Hall effect sensors are popular in industrial settings. They offer non-invasive measurement and can handle high currents. These sensors use a magnetic field to determine the strength of the current, making them reliable for equipment monitoring.

Shunt resistors are another option. They work by measuring the voltage drop across a known resistance. This method is simple and effective for low-current applications. However, shunt resistors can introduce power loss. Designers must consider this when choosing them.

In contrast, clamp-on sensors provide easy installation. They can measure current without direct contact with the conductor. This feature is beneficial in maintenance scenarios. However, their accuracy may vary under different conditions. Evaluating the specific requirements of your application is crucial. Choosing the right sensor can significantly impact performance and efficiency.

Evaluating Measurement Accuracy and Range in DC Current Sensors

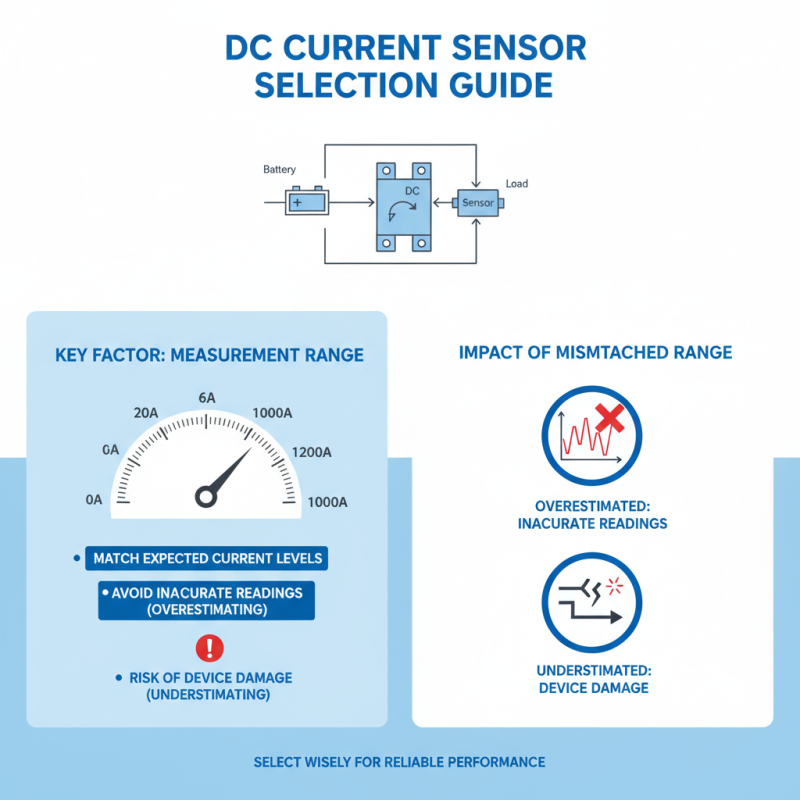

When choosing a DC current sensor, measurement accuracy is crucial. Accurate sensors provide reliable data for your applications. Consider factors like temperature, load conditions, and sensor design. Even small errors can lead to significant discrepancies. You might think a 1% error is minor. However, in critical systems, this can result in equipment malfunctions.

The measurement range of a DC current sensor also plays a vital role. Sensors must cover the expected current levels in your application. If the range is too narrow, the sensor could saturate. Conversely, an excessively wide range may compromise resolution. Finding a balance is key. You should evaluate how these factors impact your system's performance. Take into account the specific use cases you have in mind.

It's common for users to overlook these aspects. Without careful analysis, you may pick a sensor that doesn't fit. Testing sensors in real-world scenarios is often beneficial. This helps in assessing their true performance. Keep in mind that some sensors may look great on paper but underperform in practice. It's all about finding the right fit for your specific needs.

Cost-Effectiveness and Longevity of DC Current Sensors in Different Applications

When selecting a DC current sensor, cost-effectiveness and longevity are crucial. Different applications may have unique requirements. A sensor that performs well and lasts longer can save both time and money. For instance, industrial settings might demand higher accuracy and durability.

Tips: Assess the environment. Look at temperature and humidity. Sensors that withstand harsh conditions often last longer. Sometimes, investing upfront can lead to savings in maintenance.

In contrast, lower-quality sensors might seem cheaper initially. However, frequent replacements can become costly. Evaluate your needs carefully. Compatibility with existing systems should not be overlooked. Have you considered future scalability?

Tips: Check for warranties. A longer warranty often indicates confidence in the product. Ensure to read reviews to gauge long-term performance. Longevity should be a priority, especially in critical applications.

X

X

X

X  X

X  X

X