2025 How to Choose the Best Hall Current Sensor for Your Project

In the rapidly evolving field of electronics, selecting the appropriate Hall current sensor for your project can significantly impact system performance and reliability. As John Smith, a veteran engineer with over two decades of experience in sensor technologies, aptly stated, "The choice of sensor defines the foundation of your electrical design." Hall current sensors are vital components for measuring the direct current (DC) and alternating current (AC) in various applications, making their selection crucial for achieving accurate and efficient results.

When embarking on the journey to choose the best Hall current sensor, it's essential to consider several factors, including the sensor's sensitivity, measurement range, and response time. The growing demand for precision in energy management and monitoring systems further underscores the importance of understanding the specifications and capabilities of different Hall current sensors. By delving into these critical elements, engineers can ensure their projects not only meet but exceed modern standards for performance and safety.

In summary, the process of selecting a Hall current sensor is not merely a technical choice; it is a pivotal step in guiding the success of any electronics project. With a clear understanding of the key criteria, designers can harness the power of Hall effect technology to create innovative and effective solutions.

Understanding Hall Current Sensors and Their Functionality

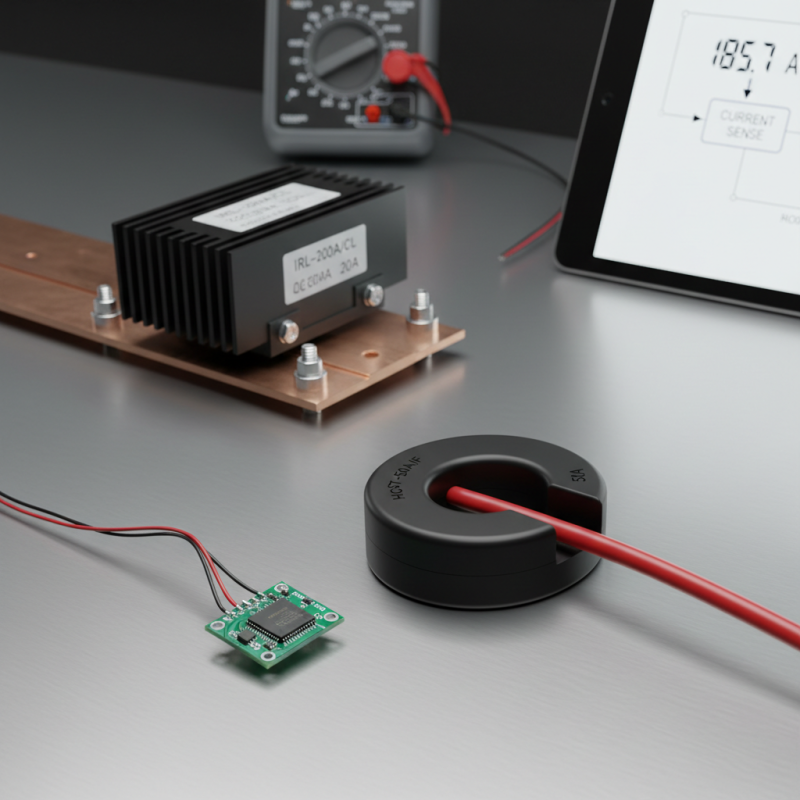

Hall current sensors are critical components for measuring electric current in various applications. Utilizing the Hall effect principle, these sensors detect the magnetic field generated by an electric current flowing through a conductor. When current passes through a wire, it creates a magnetic field perpendicular to the direction of the flow. A Hall sensor placed in this field produces a voltage output that is proportional to the current, enabling accurate and non-invasive measurement.

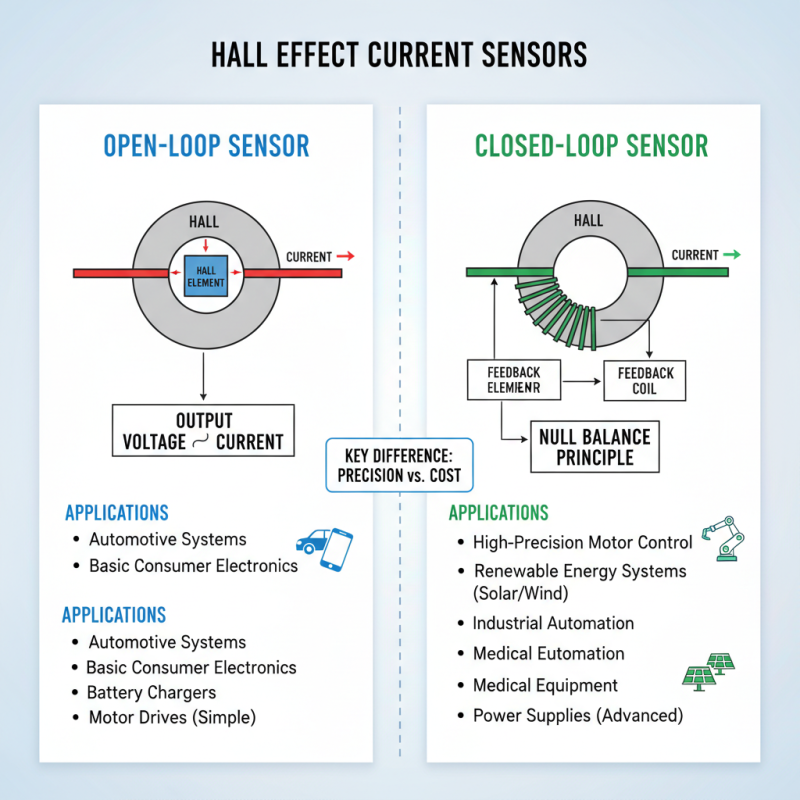

Understanding the functionality of Hall current sensors is essential for selecting the right one for your project. These sensors come in various types, including open-loop and closed-loop designs. Open-loop sensors provide a simple, cost-effective solution for applications requiring basic current monitoring, while closed-loop sensors offer enhanced accuracy and can handle larger currents, making them suitable for more demanding applications. Additionally, considering factors such as measurement range, sensitivity, and response time is crucial in ensuring the chosen sensor aligns with the specific requirements of your project, ensuring optimal performance and reliability.

Key Specifications to Consider When Selecting a Hall Current Sensor

When selecting a Hall current sensor for your project, understanding key specifications is paramount. First, consider the measurement range of the sensor, which must align with the expected current levels in your application. For instance, many industrial applications report using sensors that can measure currents from milliamps to hundreds of amps. A report by the International Electrotechnical Commission (IEC) indicates that precise selection of current sensors can improve overall system efficiency by up to 15%, highlighting the importance of this specification.

Another critical specification is the sensor's sensitivity and accuracy. It is essential to choose a sensor that provides low noise levels and high resolution to ensure that small fluctuations in current can be accurately detected. According to recent data from the Institute of Electrical and Electronics Engineers (IEEE), sensors with a resolution of less than 1% of full scale enable more reliable current measurements, which is crucial in applications where precision is key, such as in renewable energy systems or electric vehicle management.

Tips for selection: Always review the operating temperature range of the sensor to ensure it can withstand the environment in which it will be deployed. Additionally, consider the output type—analog vs. digital—based on your project needs. A sensor with a robust thermal stability rating will also provide consistent performance, which is vital for long-term applications. This careful evaluation helps to ensure that the Hall current sensor you choose will perform reliably and effectively in your specific project context.

Different Types of Hall Current Sensors and Their Applications

When selecting a Hall current sensor for your project, understanding the different types available and their applications is crucial. Hall effect sensors can generally be categorized into two main types: open-loop and closed-loop sensors. Open-loop Hall sensors measure the magnetic field produced by the current flowing through a conductor, providing a straightforward and cost-effective solution for applications requiring basic current measurement. These sensors are ideal for environments where precision is less critical, such as in automotive or basic consumer electronics.

On the other hand, closed-loop Hall sensors incorporate feedback mechanisms that enhance accuracy and linearity in current measurement. They are adept at providing more precise readings, making them suitable for applications in industrial automation, electric vehicles, and renewable energy systems. By utilizing a feedback loop, these sensors can compensate for temperature variations and other external influences, ensuring a stable and reliable performance. Depending on the specific requirements of your project, choosing between these sensor types will significantly influence both the performance and the overall success of the application.

Integration and Compatibility with Your Project Requirements

When selecting a hall current sensor for your project, integration and compatibility with your existing systems are crucial factors that can significantly influence the success of your application. Begin by assessing the electrical specifications of both your sensor and your equipment. Consider parameters such as operating voltage, current rating, and output types. A sensor that matches these specifications ensures seamless communication and functionality within your project's ecosystem, reducing the risk of malfunctions or performance issues.

Furthermore, the physical dimensions and mounting options of the hall current sensor must align with your design requirements. Evaluate the available space within your project and ensure that the sensor can be easily integrated without compromising other components. Additionally, examine the environmental conditions of your application—factors like temperature range, humidity, and potential interference from electromagnetic fields can dictate the best sensor choice. By prioritizing integration and compatibility from the outset, you can enhance both the reliability and efficiency of your overall project.

2025 Hall Current Sensor Selection: Project Requirements Analysis

This chart represents the compatibility and integration levels of various hall current sensors based on key performance metrics required for different projects. The metrics assessed include sensitivity, response time, and voltage range.

Cost Considerations and Budgeting for Hall Current Sensors

When planning a project that involves the utilization of Hall current sensors, budget considerations play a crucial role in selecting the right components. The Hall effect sensor market is projected to reach $2.8 billion by 2025, driven by the rising demand for energy-efficient solutions and advancements in technology. Understanding the financial implications of these sensors is critical for effective project management.

The cost of Hall current sensors can vary significantly based on their specifications, including sensitivity, accuracy, and output type. For example, low-end sensors may range from $1 to $5, while high-performance models can exceed $50. According to recent industry reports, balancing initial costs with long-term operational savings is key. Investing in higher-quality sensors may lead to reduced maintenance costs and improved accuracy, offering a better return on investment over time.

Furthermore, it is essential to consider additional expenses, such as integration costs and potential calibration requirements. The total cost of ownership should encompass not just the purchase price but also long-term reliability and performance metrics. A detailed budget that accounts for these factors will help in making informed decisions, ensuring that the selected Hall current sensors align with both the project's financial constraints and technical requirements.

X

X

X

X  X

X  X

X