2025 Guide: How to Choose the Right Rogowski Coil CT for Precision Current Measurement

In the evolving landscape of electrical measurement technology, the importance of precision current measurement cannot be overstated. According to a recent market research report by Research and Markets, the global demand for current transformers, including Rogowski coil CTs, is projected to reach USD 5.2 billion by 2025, reflecting a significant CAGR of 6.9% from 2020. This growth underscores the critical role that accurate and reliable current measurement systems play in various industries such as power generation, renewable energy, and electrical infrastructure.

Choosing the right Rogowski coil CT is essential for ensuring optimal performance and measurement accuracy. Unlike conventional CTs, Rogowski coils offer distinct advantages such as a wide frequency response and the ability to measure high currents without saturation, making them ideal for both transient and steady-state applications. In an age where energy efficiency and monitoring are increasingly prioritized, understanding the technical specifications and application suitability of

Rogowski coil CTs becomes imperative for engineers and technicians. This guide aims to provide comprehensive insights to aid in the selection process, ensuring that users can leverage the full potential of this advanced measurement technology.

Understanding the Fundamentals of Rogowski Coil CT Technology for Current Measurement

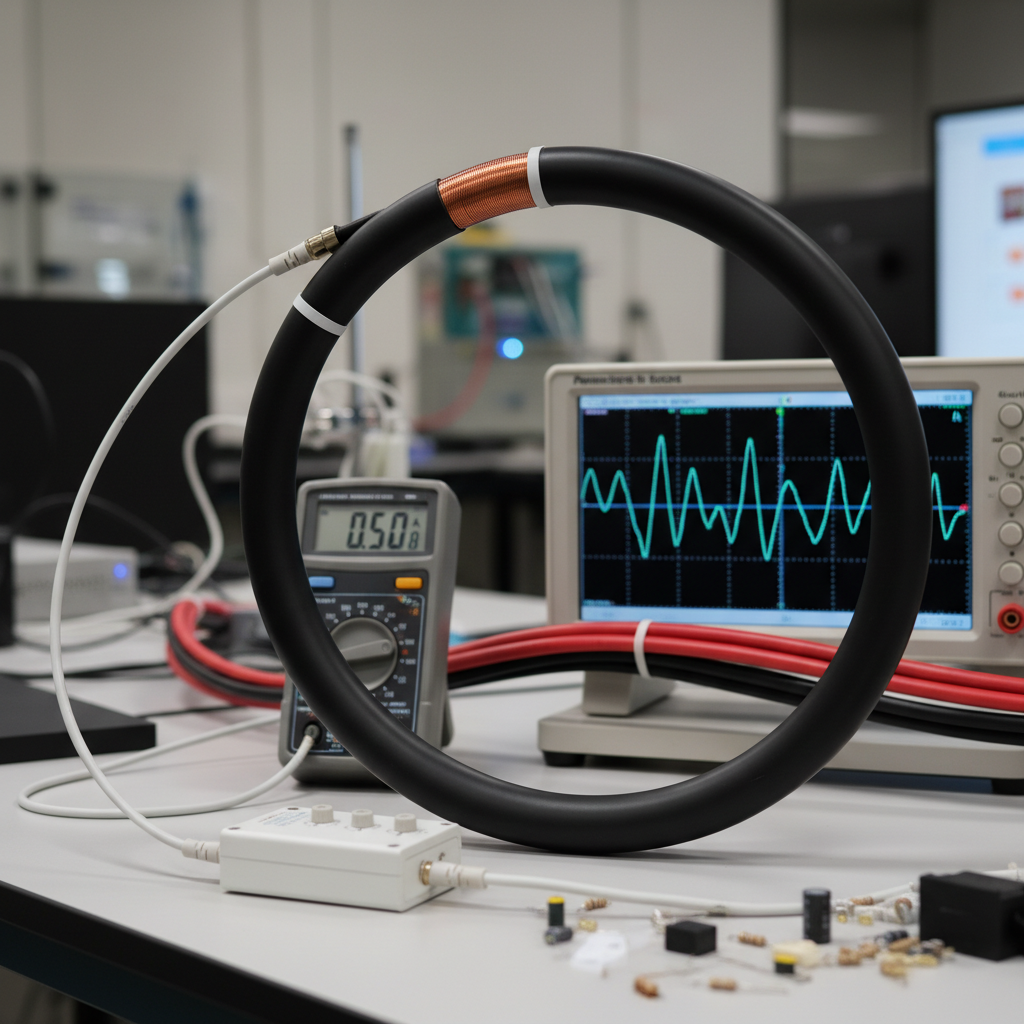

Rogowski coil current transformers (CTs) are widely recognized for their ability to provide precise current measurements in various applications. At the core of their technology lies a flexible, toroidal shape that allows for easy installation around conductors. This design not only accommodates a wide range of conductor sizes but also ensures minimal magnetic interference, enhancing measurement accuracy. The fundamental operating principle relies on the coil's ability to produce a voltage that is proportional to the rate of change of the current flowing through the conductor, making it particularly suitable for measuring alternating currents.

Understanding the essential characteristics of Rogowski coils is crucial when selecting the right CT for specific applications. Key parameters include sensitivity, frequency response, and the coil's physical dimensions. Sensitivity affects the minimum measurable current, while frequency response determines how well the coil can track changes in current over time. Additionally, the choice between a portable or an integrated coil design can influence both installation convenience and measurement reliability. By thoroughly assessing these fundamentals, users can ensure that they choose a Rogowski coil CT that meets their precision current measurement needs effectively.

Key Specifications to Consider When Selecting a Rogowski Coil CT for Optimal Performance

When selecting a Rogowski coil current transformer (CT) for precision current measurement, there are several key specifications to consider for optimal performance. One of the primary factors is the coil's sensitivity, which indicates how effectively it can detect current changes. A higher sensitivity ensures more accurate readings, especially in applications where precise measurements are critical.

Additionally, consider the frequency response range; the ability to monitor varying current frequencies is essential for accurate power analysis in industrial setups.

Tips: Ensure that the Rogowski coil you choose is compatible with your existing monitoring systems to enable seamless integration. Look for coils with robust construction and materials that can withstand environmental factors, especially if used in harsh industrial settings. Finally, pay attention to the positioning error in CTs, as advancements have recently minimized this to just around 2%, enhancing overall measurement precision.

Incorporating Rogowski coils in your facility can significantly improve power monitoring and reduce downtime. The latest advancements in Rogowski technology have introduced split-core designs that facilitate easier retrofitting of your plant’s monitoring systems. This innovation not only enhances real-time asset monitoring but also shortens installation time, which is crucial for maintaining operational efficiency.

Evaluating Accuracy and Linearity: Essential Factors in Rogowski Coil CT Selection

When selecting a Rogowski coil current transformer (CT) for precision current measurement, evaluating accuracy and linearity is paramount. These factors directly influence the performance and reliability of measurements in various applications. Accuracy is a measure of how close the measured value is to the true value. In traditional Rogowski coils, positioning errors often limited this accuracy to about 2%, which could introduce significant discrepancies in critical measurement tasks.

Recent advancements in Rogowski coil technology have addressed these limitations by providing enhanced performance in positioning accuracy. The new generation of split-core Rogowski coil transducers aims to minimize positioning errors while improving overall measurement fidelity. This innovation allows for more reliable current measurements, essential in applications that require high precision, such as monitoring in energy systems and industrial processes. Thus, when choosing a Rogowski coil CT, it is crucial to look for models that offer improved accuracy and linearity to ensure optimal performance in current measurement tasks.

2025 Guide: How to Choose the Right Rogowski Coil CT for Precision Current Measurement

| Parameter |

Description |

Value/Range |

Importance |

| Accuracy |

The degree to which the measured value conforms to the true value. |

±0.5% to ±1% |

High |

| Linearity |

The ability to produce output that is proportional to the input over a range. |

<1% deviation |

Critical |

| Frequency Response |

Range of frequencies over which the coil can effectively measure current. |

1 Hz to 100 kHz |

Moderate |

| Temperature Coefficient |

Change in accuracy with temperature variations. |

±0.05%/°C |

High |

| Dynamic Range |

Range of current values that can be accurately measured. |

1 A to 5000 A |

High |

Comparative Analysis: Rogowski Coil CT vs. Traditional CTs in Precision Applications

When selecting a current measurement solution for precision applications, the choice between Rogowski coil current transformers (CTs) and traditional CTs is pivotal. Traditional CTs, while widely used, often face limitations in terms of accuracy at high frequencies. According to a report by the International Electrotechnical Commission (IEC), traditional CTs can introduce phase errors exceeding 5% in systems with high harmonic content. In contrast, Rogowski coils are renowned for their broad frequency response, capable of delivering accurate measurements up to several megahertz without the saturation issues that plague traditional designs.

Additionally, Rogowski coils offer significant advantages in terms of installation and adaptability. Their non-intrusive design allows for easy placement around conductors of varying sizes and shapes, making them ideal for retrofitting into existing systems. The National Institute of Standards and Technology (NIST) has highlighted that the flexibility of Rogowski coil CTs leads to reduced installation times and costs, often up to 30% less than traditional CT setups. As precision applications continue to evolve, the increasing reliance on high-frequency equipment further underscores the need for measurement solutions that can maintain accuracy without compromising performance.

Emerging Trends in Rogowski Coil Technology: What to Expect by 2025

As we approach 2025, the Rogowski coil technology is poised for significant advancements, driven largely by the increasing demand for precision current measurement across various sectors. The global current sensor market is projected to grow from $3.40 billion in 2025 to $6.67 billion by 2032, highlighting a robust CAGR of 10.10%. This growth is primarily fueled by the surge in electric vehicle (EV) adoption, leading the automotive current transducer market to an expected value of USD 881.3 million by 2033.

The evolution of Rogowski coil technology is expected to feature enhanced accuracy and reduced form factors, making these sensors more suitable for integration in compact spaces. As industries continuously seek innovative solutions, the need for lightweight and flexible sensors will drive further research and development in this field.

**Tips for Choosing a Rogowski Coil CT:**

1. Consider the operational range and accuracy required for your specific application.

2. Look for coils that accommodate different cable sizes and provide interchangeable outputs for flexibility.

3. Evaluate the coil's bandwidth and slew rate to ensure it meets the dynamics of your measurement environment.

2025 Guide: How to Choose the Right Rogowski Coil CT for Precision Current Measurement

This chart illustrates the advancements in Rogowski coil technology and the expected improvements in measurement accuracy over the next few years.

X

X

X

X  X

X  X

X